Safety Engineering in Construction Industry

Part 1-Introduction

What is ‘Safety Engineering in Construction Industry’ ?

With the modern technology today much advanced equipment is used in construction industry. By using those equipment people do dangerous operations. Moreover, they use hazardous materials. Engineer is a person, who adopts methods and use devices which will reduce the risks to the physical body, mental body, health etc. Not only safety but also the efficiency of working also should be considered. Hence, the engineers have to choose hazardous equipment to improve the efficiency. Then what does happen to the workers? This became a major problem. Safety Engineering gives a solution to this problem. This will improve not only efficiency but also safety of the workers.

However, the supervisory tasks become very important in construction fields. The supervisors should check whether the workers follow the rules for safety. Otherwise, supervisors are responsible for that. Not only workers, but also the manufacturers of equipment should also follow the safety rules.

In safety engineering the word “safety‟ also includes the health of the worker. For an example working in a dusty construction field without wearing air filters does not affect the worker suddenly. However, in future he will face respiratory deceases. The engineers and supervisors should response for that.

Safety Engineering In Construction Industry in Brief

If we consider above description we can get all those things into few words. That is called as the core concept of the “The Safety Engineering in Construction Industry”.

“Safety engineering in construction industry is a process of designing working fields by using the principles of safety, not only to prevent sudden hazards, but also to prevent future bad results. And this include modes to reduce accidents by risk management process to identify and remove hazards”

In next section we are going to discuss about construction related hazards, which were reported in past few years.

Part 2-Recent Hazards and Analysis in Construction Industry

Although safety engineering was introduced there are some hazards are still happening due to many reasons. Among them some are mentioned below.

- In 2014, the United States had 4,679 fatal injuries. The rate was 3.3 per 100,000 full time employed workers. In same year, fatal injuries due to work in construction and extraction occupation increased 5%. Construction related workers were one-fifth of above value. In US constructor related workers were 6%. But 17% of fatalities were constructor related workers.

- In UK 31% of fatalities and 10% major injuries were responded by construction fields.

- Each year, there are approximately 400 injuries and 150 fatalities in construction sites in South Africa.

- In Brazil incident rate for all occupational fatalities is 3.6 per 100,000.

Now we are going to discuss about the core Principles of Safety Engineering.

Part 3-Principles of Safety Engineering in Construction Industry with examples

We must plan on system safety and how to increase it. For that we require not only trained, but also experienced staff in safety engineering. This plan must influence facilities, equipment, procedures and personnel. If we consider about construction industry, then this plan must include transportation, storage, packing etc. However, system safety requirements must be balanced with other program requirements. A balanced program attempts to optimize safety as well as performance and cost. Furthermore, program cannot afford accidents that will prevent the achievement of the primary goals.

To achieve these goals with high safety, high performance and low cost, we are using the core principles of safety engineering. Those principles are mentioned below.

1) Hazard Identification

2) Hazard Evaluation

3) Hazard Control

Let us discuss these principles separately with examples.

1) Hazard Identification

The Hazard Identification is the first principle in safety engineering. First of all we must know what is meant by the word “Hazard‟. Actually hazard is a thing, which brings harm to a person or thing. It is important to identify such a hazard before it cause harm. Many techniques related to system safety management have been used to help in identification of potential system hazards. Potential hazards associated with various physical systems and their associated operations. These operations include common industrial and consumer related activities. These can be identified easily by recognizing system products and product hazards which are directly related to various common forms of energy. Hence, hazards (damage, injury, etc.) cannot occur without the presence of some form of hazardous energy. So hazard identification is a type of energy identification. This hazard identification recognizes unexpected, inappropriate release or exchange of energy in a system. This energy is a necessary factor to happen an accident.

In above paragraph, we talked about energy as a requirement to happen a hazard.

Actually we know that hazard identification is a part of risk assessment. In below we have mentioned a proper definition for hazard identification.

“Hazard identification is the process of examine all working areas and tasks to identify all the hazards, which are included in the works/jobs. That is, this is the process about finding what could cause harm in tasks or areas.”

This includes machine workshops, laboratories, office area, stores, transport, field maintenance, etc.

This include using screen based equipment, dealing with emergency situations, industrial equipment and hazardous substance, teaching the people, dealing with people, driving a vehicle, using audio and visual equipment, construction, etc.

After that, we are going to consider about some hazard identification related to construction industry with examples.

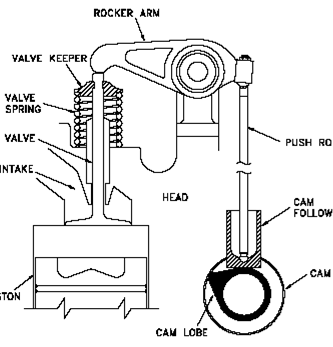

First of all, we are going to talk about some hazards related to mechanical section that can be happen in a construction industry.

These hazards involves with the system hardware components which is used to cut, crush, bend, pinch, pull, wrap, shear materials used in construction industry. If the operator does not care about the safety engineering instructions, then he/she will face some hazardous situations.

However, we must identify these mechanical hazards. To these we must check flywheels, pulley bells, belts, chains, couplings, cranks, gears etc. Besides, we must identify hazardous area in/near machines. Such as the area between rotating parts, area near tangential parts, the area near crushing parts etc. Identifying those sections are coming under hazard identifications.

Then we are going to talk about non-mechanical hazards.

Now we must consider how to identify those non-mechanical hazards.

To this, we must check whether there are safety nets are applied to protect from falling. If not applied we must identify those places as hazardous areas. We should check for signs, which mention the worker about the hazard that can be happened. We must identify the moving objects and their speeds, masses, etc. to check whether it is a kind of hazard. We must identify slippery floors, noisy areas, and electric shorts by using related equipment and so on.

In above paragraph, I have mentioned little types of hazard identifications in a construction industry.

Although, the points mentioned above on „Hazard Identification‟ are very little, “Hazard Identification” is a topic which covers a huge range. However, at next we are going to discuss about ‘Hazard Evaluation”.

2) Hazard Evaluation

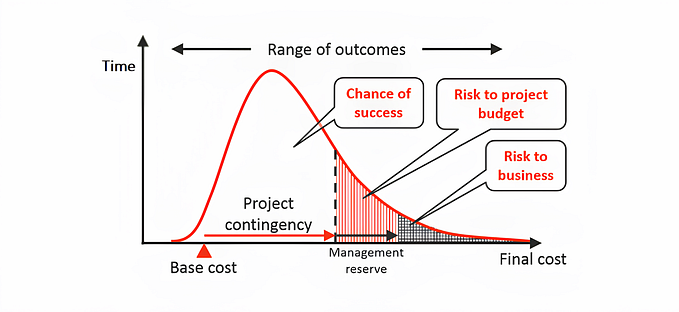

The goal of this stage is prioritizing/ordering the list of potential hazards compiled in hazard identification. Actually, we cannot measure the potential danger of a potential hazard by its appearance. Now a problem rises. That is ‘How can we measure the potential danger of a potential hazard?’

Risk factors supply a good solution for this problem. Risk can be measured as the product of three components.

I. The probability that an injury/damage producing mishap will occur during anyone exposure to the hazard.

II. The likely severity/degree of injury/damage that will like result should a mishap occur.

III. The estimated number of times a person or persons will likely be exposed to the hazard over a specific of time. That is,

H = Hazard P = Probability R = Risk S = Severity D = Danger

In evaluation we should consider about historical incident data and reasonable methods of prediction. Besides, there are some factors, which contribute to the level of risk. Some of them are,

Furthermore, there are various types of hazard evaluation techniques exists. Those are,

A. Qualitative Techniques

- Preliminary Hazard Analysis

- Checklist

- What-If Analysis

- What-If/Checklist Analysis

- 2Guide Word Analysis

- Hazard And Operable Analysis

- Failure Modes And Effects Analysis

B. Quantitative Techniques

- Layer Of Protection Analysis

- Dow Fire And Explosion Index

- Dow Chemical Exposure Index

- Fault Tree Analysis

- Event Tree Analysis

- Human Reliability Analysis Event Tree

3). Hazard Control

We know that the primary purpose of engineering is physically control various materials and processes to produce a specific benefit. The central control of safety engineering is the control of system hazards. The principle related to that is “Hazard Control”.

We must control hazards by using following steps,

I.Remove the hazards, which we can remove from the field.

II.Use safeguard methods to hazards, which we cannot remove from the field.

III.Use warning and instructions to control hazards, which we cannot remove or use safeguard methods.

These control methods are called as the “Cardinal Rules of Hazard Control”. Let us discuss about cardinal rules with examples.

1). Cardinal Rule 1

The first cardinal rule of hazard control is “Hazard Elimination”. That is, control potential hazards by designing them out of the field. For this we can do things like below,

- Remove Hazard from field

- Substitute Hazard

- Isolate Hazard

- Attenuation Hazard

at the beginning of the field planning process.

2). Cardinal Rule 2

The next cardinal rule of hazard control is not about remove hazard. It is about minimize of hazards through safety features and safety devices of engineering. According to these rule the industry must make compulsory to use personal protective equipment in the field. By wearing this equipment the workers can protect their selves from non-removed hazards. Therefore the workers‟ motivation will high and the productivity will increase.

In below I have mentioned a list of equipment which is used in construction industry.

- Mask to prevent from dusty air

- Glasses to protect eye

- Metal gloves for workers, who work with machines

- Metal layered shoes

- Hearing protection Tools (Ear protection tools)

3). Cardinal Rule 3

Last cardinal rule of hazard control is the control of hazards by using warnings and instructions. That is, control hazards by using effective communication methods. Let us discuss about the tasks of warning and instruction signs in construction industry.

This is used to warn the worker/person about the associated system hazards that may potentially be come across under reasonably foreseeable condition of system use, misuse or service.

The signs which instruct about the precise steps/actions that should be taken/followed to avoid potential hazards.

However the method of using warning and instruction signs is the least effective method of hazard control.

Part 4-Why risk management in Safety Engineering in Construction Industry is important

There are a plenty of importance of safety engineering that we can list. Few of them are mentioned below.

- Safety engineering helps to access the objective of the project successfully.

- The cost of predict risks early far exceeds the negative impact when the risk event occurred.

- It allows decreasing the possibility of negative impacts, but increasing the possibility of positive incidents.

- It helps to identify new opportunities early. If planned early we can convert a negative risk to a positive one.

- Enhances the ability to control project‟s implementation as we know and planned for things that can go wrong in project. Besides, we have already planned what we should do when it occurred.

- It allows the project manager to take effective decisions.

- It helps organizations to avoid the negative impacts of litigation.

- It assures workers safety. So workers are motivated by this. Furthermore, they work with good mentality. Then the productivity will increase automatically.

Part 5-How to manage hazards in Construction Industry

In above part I have mentioned the importance of hazard management.In below, I mentioned few solutions to manage hazard.

- Create a safety culture in work place.

Safety culture in a work place means a culture followed in workplace by set/group of workers to maintain a risk free environment. For this first of all the workers must follow good safety practices by their own. Actually this can‟t build by a one single worker. However, if everyone tries and builds a safety culture eventually everyone will be safe.

- Good Leadership.

Company leaders should be at the core of the safety initiatives. Their positions as leaders, they should care about the workers and their safety level. They must supply safety equipment, instructions etc. to the workers.

- Implement a Hazard Identification and Assessment Plan.

- Collect and review existing information on working field Hazards.

- Inspect the workplace for new or existing hazard.

- Update Hazard reports.

- Identify hidden hazards that will affect the health.

- Conduct seminars on „safety management‟ to the workers.

- Buy new equipment, which are more safety than old one.

- Give a good training to workers.

Word by word eventually we have reached to the last part of this report. In this part let us analyze what we discussed so far.

First, we got a good introduction about “safety engineering in construction industry‟. Then we discussed about the recent hazards in construction industry with examples. After that we paid our attention to the principles of safety engineering in construction industry with examples. Under this topic we discussed about Hazard Identification, Hazard Evaluation, and Hazard Control. In the section of hazard control we discussed about three cardinal rules. Then we talked about “Why risk management in safety engineering is important?”. In previous part, we discussed about the solutions which can be taken to manage hazards in construction industry.

Finally, we experienced that, this report shows the importance of the “Safety Engineering Section”. Even if we discussed this topic with construction industry, these things can be used in huge range of fields. Eventually, it is good to mention that the word “Safety Engineering” is a one of the most significant words in each engineering field.

Part 6-References Used

The references used to write this report are mentioned below.

References

(n.d.). Retrieved from Google Images: https://images.google.com/

(n.d.). Retrieved from https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=5&cad=rja&uact=8&ved=2ahUKEwiVkvL8_tDgAhUR148KHTDgBqoQFjAEegQIBxAC&url=http%3A%2F%2Fegyankosh.ac.in%2Fbitstream%2F123456789%2F31688%2F1%2FUnit-1.pdf&usg=AOvVaw0oketDT-nIxKKM0YAbXyXt

Core Principles of Safety Engineering. (n.d.). Retrieved from Nelson & Associates: http://www.hazardcontrol.com/factsheets/principles/core-principles

4 Ways to Control Hazards and Risk in the Workplace. (n.d.). Retrieved from https://www.ehsinsight.com/blog/4-ways-to-control-hazards-and-risk-in-the-workplace

Cardinal Rules of Hazards Control. (n.d.). Retrieved from

https://kktmadhusanka.blogspot.com/2016/11/cardinal-rules-of-hazards-control.html

common-construction-hazards. (n.d.). Retrieved from highspeedtraining: https://www.highspeedtraining.co.uk/hub/common-construction-hazards/

Construction_site_safety. (n.d.). Retrieved from wikipedia: https://en.wikipedia.org/wiki/Construction_site_safety

Safety Engineering Concepts. (n.d.). Retrieved from SafetyInfo: https://www.safetyinfo.com/engineering-concepts-safety-index/

Thank You. Hope this was very useful. Stay Safe.